![]() 400-850-1759

400-850-1759![]() China

China

![]() 400-850-1759

400-850-1759![]() China

China

Yanmao Intelligent Equipment (Suzhou) Co., Ltd.

Contact: Ren Hongbing

Mobile: 18016000798

Landline: 0512-53635091

Fax: 0512-53635090

QQ: 18016000798

Website: www.zbsmdj.cn

Address: No.8, Xingsheng Industrial Park, 11 Xingye South Road, Taicang City, Jiangsu Province

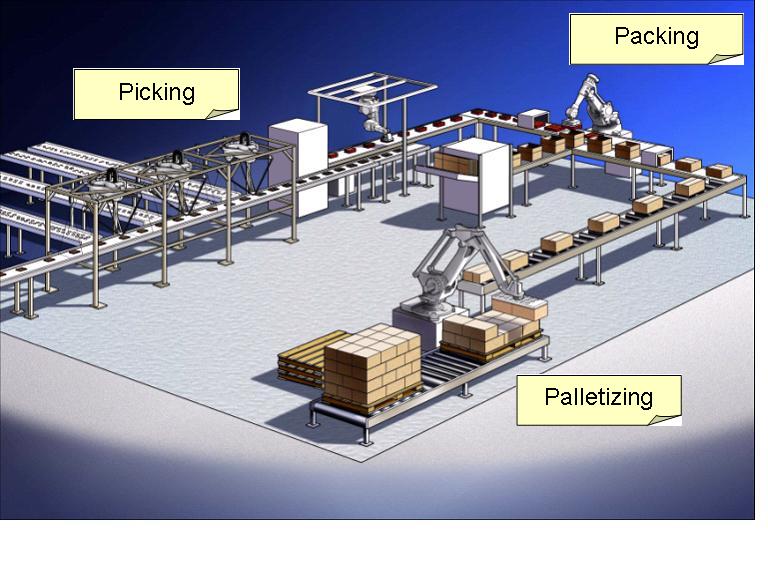

Palletizing robots are designed primarily for packaging applications and are compact enough to be integrated into a compact packaging machine while meeting all your requirements for reach and payload. With motion control and tracking capabilities, the robot is ideally suited for flexible packaging systems, greatly reducing packaging cycle time. With its extremely high accuracy, coupled with its superior belt tracking performance, the pick-and-place precision is top notch, both in fixed position and in motion. Small size, fast, specially optimized according to the packaging application, is the inevitable choice of robot automation. Equipped with a full complement of accessories (from integrated air and signaling systems to the gripper), package software is available that is easy to machine and easy to program. High-speed robot with the most advanced 4-axis design, 3.15m reach and 250kg payload is ideal for packing and stacking materials in packages such as bags, boxes, crates, bottles and more. Suitable for harsh environment applications, degree of protection to IP 67. Robotic versatility, reach and load-bearing capacity meet virtually any stacking application.

Boxing robots are ideal for applications that need to move objects quickly and accurately from place to place (one at a time). In addition, the accuracy of the system is so high that the robot chooses only the good and ignores the defective objects (such as cookies, chocolates, pills, etc.). The structure is very simple and consists of just a few components, which is why it lasts longer than a rigid automation solution. Mean time between failures (MTBF) of 135,000 hours. The fastest robot of its kind. Designed for fast pick and place, up to 150 picks per minute can be done with a corresponding cycle time of 0.4 seconds. The maximum acceleration of 10g, IRB 340 is currently the fastest acceleration of the world's robot. The robot cycles up to 180 cycles per minute. The palletizer's payload weighs 2kg. Available in stainless steel version, the IRB 340 robot is ideal for operations requiring extreme cleanliness. The stainless steel IRB 340 robot is ideal for use in the food, pharmaceutical, medical and electronics industries. The robot is top-mounted, occupies no indoor area and is easy to integrate. With PickMaster software, the IRB 340 robot is the most flexible robotic solution for high-speed pick-and-place applications.

• Reliable - uptime

• Fast speed - short cycle time

• High precision - parts production quality and stability

• Powerful - wide range of applications

• Rugged - suitable for harsh production environments

• Versatile - Flexible integration and production